Public Online Auction

Location:

1551 Dell Avenue

Campbell, CA 95008

Opens:

July 1, 2025

8AM

Closes:

July 22, 2025

Inspection:

July 21, 2025

8:00 AM TO 3:00 PM PT

Auction Brochure Auction Lot Catalog Proxy Bid Form

TERMS AND CONDITIONS (Please read full Terms when registering):

THIS SALE IS ONLINE ONLY. REGISTER AT WWW.BIDSPOTTER.COM.

***INVOICES WILL BE SENT OUT AFTER THE BIDDING ON 3RD DAY IS CLOSED***

***All sales in U.S. dollars !!***

***FULL AND FINAL PAYMENT MUST BE MADE BY ACH or WIRE TRANSFER BY 7/29/2025.***

***BUYERS PREMIUM IS 18% OF HAMMER PRICE.***

*** All items are sold “AS IS, WHERE IS” without any warranty, expressed or implied. NO EXCEPTIONS. ***

*** This is a three-day sale. Lots will be closing on 7/22, 7/23 and 7/24. Please make sure you know when your lot is closing ***

Register once and bid all three days:

|

DAY 1 |

Vertical Machining Centers and Manual Equipment |

Click here to see the lot listing |

| DAY 2 |

Lathes and All plant support (forklifts, etc..) |

Click here to see the lot listing |

| DAY 3 |

Electric Discharge Machines and Inspection |

Click here to see the lot listing |

REMOVAL:

ALL REMOVAL IS STRICTLY ON AN APPOINTMENT ONLY BASIS! If you do not make an appointment you may be turned away.

Buyers are responsible for all prepping, loading and shipping.

Anyone prepping and removing purchased items with a lift truck or another powered vehicle must have a CERTIFICATE OF INSURANCE with a $1M General Liability policy, the policy must include a Worker’s Compensation rider, and that certificate of insurance must be provided to the auctioneer for review and approval prior to the auction.

Buyer must remove all purchased lots from facility with all parts, pieces and accessories.

- Removal Dates & Time: From Monday, July 28 through Friday, August 15, 2025, between 8:00 AM to 4:00 PM. NO REMOVAL DURING AUCTION OR ON FRIDAY, July 25, 2025

- Removal Contact: Drew Kirkendall (520) 982 – 1732

PREPPING LARGE MACHINERY: For any prepping help please reach out to these service technicians directly:

D&L Precision Rebuilding 650-365-8589

Selway Machine (Haas / Matsuura Machines) 888-735-9290

Gosiger Machine (Okuma Machines) 925-371-2333

RIGGING AND LOADING

Approved rigger: American Rigging, Bill Belcher 800-533-4178

THREE-DAY MAJOR AUCTION SALE

DAY 1 – Vertical Machining Centers and Manual Equipment See items

Day 2 – Lathes and All plant support (forklifts, etc..) See items

Day 3 – Electric Discharge Machines and Inspection See items

FEATURING:

CNC LATHES:

- 2011 Okuma Multus B400-W, with Chip Blaster High Pressure Coolant model EV60, Okuma OSP-P200LA Control, Tool Setter, Parts Catcher, 15″ Chuck Main Spindle, 10″ Chuck Sub Spindle, Chip Conveyor, 40 ATC for mill spindle, S/N: 156141

- LNS quick Load Servo S3-L, with with Multis b400, S/N: 314115

- 2003 Okuma IMPACT LU45, with OSP E100L Control, , Tailstock, 12 station Turret, 10 Station Sub Turret, Enomoto Chip Conveyor, Airflow system mist collector, S/N: 103253

- 2011 Mori Seiki NLX2500SY/700, with Live tooling, LNS Chip Conveyor, main spindle 4000 Rpm, Sub spindle 6000 rpm, 10″ chuck and 6″ chuck sub, S/N: NL254KE0097

- 2011 ATS ML-580, with bar feed with Mori Seiki NLX, S/N: 222480

- 2014 Okuma Genos L200E-M, with OSP -P300 Control, Collet Chuck, Live Tooling, 12 Station Turret, Chip Conveyor, S/N: 2EMY185

- 2001 Okuma LT10-MY, with Twin 12 Station Turrets, Sub Spindle 5000 RPM, Main Spindle 6000 RPM, Collet Seed Chucks, Okuma OSP-U100L Control, Live tooling ready, Chip Conveyor, S/N: 1303-0431

- LNS Quick Load Servo S2, with With Okuma LT10-MY, S/N: 301678

- 2001 Okuma Captain – L370MW, with Okuma OSP u100L Control, Tool Setter, 10″ Chuck, Tailstock, Hennig Chip Conveyor, S/N: 230

- Okuma Cadet LNC8, with 8″ Chuck, Tailstock, 12 Station Turret, Okuma OSP700L Control, S/N: D403

- Okuma Space Turn LB300-M, with Chip Conveyor, Tool Setter, Parts Catcher, 12 Station Turret, 8″ Chuck, Live Tool ready, Tailstock, OSP-U100L Control, S/N: 129

- LNS Stretch 4ft, with Barfeed with Space turn s/n 129, S/N: 309108

- 1995 Okuma Impact LU15, with Jorgenson Chip Conveyor, Okuma OSP700M Control, S/N: 348

- 2000 Okuma Space Turn LB300-M, with Live tool ready, Hennig Chip Conveyor, 6″ Chuck, 12 Station Turret, Tailstock, Okuma OSP-U100L, S/N: 1423

- 1999 Hitachi Seiki TS15, with Seicos Sigma 21 L Control, Collet Speed Chuck, 12 Station turret, Tool Setter, Mayfran Chip Conveyor, S/N: TS15246

- 1988 Mori Seiki SL-25B, with Fanuc 10T Control, 12″ Chuck, Tool Setter Arm, 10 Station Turret, Tailstock, S/N: 1256

SCREW MACHINES:

- 2004 Star SR-20R II, with LNS SUPER HYDROBAR Barfeed model 3.20 HS-4.8 s/n 42842, FANUC 18I-TB control, S/N: 0617 (058)

- 2003 Citizen Cincom L20 VIII, with CITIZEN CAV20L-IS BARFEED S/N CAV0292, COOL BLASTER HIGH PRESSURE COOLANT PUMP, S/N: 13267

- Star SA-12, with LNS SUPER HYDROBAR Barfeed model 3.16 HS-4.8 s/n 41661-2001, FANUC 18I-TB control, S/N: 1172 (083)

- 1997 Citizen Cincom L25, with LNS HYDROBAR BARFEED MODEL 3.26 HS-4.8, S/N 39209-97, S/N: V6324

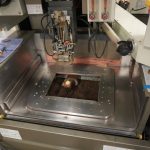

ELECTRICAL DISCHARGE MACHINES:

- 2008 Mitsubishi EA12VM Advance, with Mitsubishi FP80V Power Supply, ATC, Kuowa Liquid Tuner Model GK-50-LFV-BJ-C, S/N: 58E1A062

- 2003 Mitsubishi VA10M, with Mitsubishi 3robomatic system 3R, Mitsubishi FP60VA Power Supply, Mitsubishi C21EA-2 Control unit, Mitsubishi HE-UV3-04 Unit Cooler, S/N: 03MV1031

- 2000 Mitsubishi EA8, with Mitsubishi FP60EA Power Supply, Mitsubishi C21EA Control, Remote jog control, S/N: 59A08116

- 2004 Mitsubishi VA10M, with Mitsubishi FP80V Power Supply, Mitsubishi HE-UV3-04A, S/N: 04MV1049

- 2000 Mitsubishi VX20, with Mitsubishi FPII FP100 Control model C11 FP100, 3Robomatic System 3R, System 3R Tool Holders, Mitsubishi Unit Cooler HE-UV300-02 Unit Cooler, 20 ATC, S/N: 00V20243

- Mitsubishi FA10PM, with Mitsubishi Unit Cooler HE-SV50-W1, Powergy power conditioner model CPS-3Y208/240, Mitsubishi water filters, remote Job, Mitsubishi W21FAP-2 Control, S/N: 03F1P119

- 2005 Mitsubishi FA10SM, with Mitsubishi W21FAS-2 Control, Mitsubishi Unit Cooler HE-SV50-W2, S/N: 55D1S301

- Mitsubishi FA10PM, with Mitsubishi Unit Cooler HE-SV50-W1, Mitsubishi W21FAP-2 Control, Remote Jog, Powergy AC Power Conditioner Model CPS-3Y208/240, S/N: 04F1P215

- 2007 Mitsubishi FA10S Advance, with Mitsubishi W31FSA-2 Control, Mitsubishi Unit Cooler HE-SV50-W2, S/N: 57D1A095

- Mitsubishi FA-20S, with Mitsubishi Unit Cooler HE-SV50-W2, Mitsubishi W21FAS-2 CONTROL, Powergy AC power conditioner model CPS-3Y208/240, S/N: 04F2S005

- 2002 Agie Agiecut Excellence 2F, with Agiecut Agievision Control, S/N: 171

- 2004 Agie Agiecut Progress 3, with Agiecut Agievision Control, Cabinet (IPG-CNC 02D), S/N: 92

- 2006 Charmilles Robofil 240CC, with Remote jog, Work lights, S/N: 921568

- 2010 Agie Charmilles FI 440 ccS, with A23 Cabinet s/n 191, S/N: 136

- 2002 Charmilles Robofil 240, with, S/N: 920647

- 2004 Agie Agiecut Vertex, with Control Cabinet (IPG + CNC 02D), S/N: 46

- 2018 Agie Charmilles Cut 1000, with, S/N: 591.035.005.0094

- 2004 Mitsubishi EA12V, with Mitsubishi FP80V Power Supply, Mitsubishi Unit Cooler SAN-1500-01, S/N: 54E1V068

- 1997 Elenix EDMDrill T300, with SRJ Controller, ST300C EDM Hole driller, Ebbco Metaworking filtration system model HRF-155-LP, S/N: 83185

- 1999 Elenix EDMDrill CT500F, with With Elenix SRJ-2C-K Controller, EDM DRILL Electrode / Guide Changer, Ebbco Package Filtration System, S/N: 247

CNC MILLS:

- 2000 Matsuura MAM72-3VS, with 240 Tool ATC, Fanuc Control, Cat40, Pallet changer, Chip Conveyor, S/N: 414193

- 2010 Matsuura MAM72-35V, with Matsuura G-Tech 3M control, Mosnic Chip Conveyor, 32282 Cut Hours, Cat40, Pallet changer, S/N: 18205

- 2002 Hitachi Seiki VT500, with Seicos Lambda 16m Control, 30 ATC, Cat40, S/N: VT-50007

- 2007 Haas VF-3SS, with 24+1 Side mount ATC, Royal Mist collector, S/N: 1060662

- Haas TR160, with 5 axis Trunnion on VF-3SS 1060662, S/N: 910896

- 2014 Okuma Genos M560-V, with LNS Turbo HB Chip Conveyor, 5th axis wiring, OSP-P200MA Control, 6580 Hours as of 5/6/25, S/N: 178734

- 2016 Nikken 5AX201, with On Okuma Genos 178734, S/N: 5624

- 2013 Okuma Genos M560-V, with 10994 Hours as of 5/6/25, Okuma OSP200MA Control, S/N: 165433

- 2013 Okuma Genos M560-V, with 4th Axis Wiring, 9077 cut hours as of 5/6/25, S/N: 166019

- Tsudakoma 4th axis Rotary, with Rotary on Genos 166019

- 2013 Okuma Genos M560-V, with LNS Chip Conveyor, 8786 Hours as of 5/6/25, S/N: 167414

- 2013 Okuma Genos M560-V, with LNS Chip Conveyor, 11005 Cut hours as of 5/6/25, S/N: 166769

- Okuma MD-45VAE, with Okuma OSP-u100M Control, Chip Conveyor, S/N: 2366

- Okuma MX-45VAE, with OSP7000M Control, 30 ATC, Remote Jog, S/N: 10049267

- Okuma MX-45VAE, with OSP7000M Control, Remote jog, S/N: 11029426

- Okuma MX-45VAE, with OSP7000M Control, Remote Jog, S/N: 11039438

- Okuma MX-45VAE, with OSP7000M Control, Remote Jog, S/N: 11039439

- Okuma MX-45VAE, with OSP-U100L, Remote Jog, S/N: 9039012

- 2006 Doosan DMV 5025/50, with Fanuc Series 21i-MB Control, Hennig Chip Conveyor DMV 4020, CAT 50, S/N: AV630827

- 2001 Haas VF-3, with 24+1 Side mount ATC, Programmable Coolant, Chip Auger, Remote Jog, 17186 hours 657572 tool changes, S/N: 26921

- 2006 Haas VF-2, with 24+1 Side Mount ATC, Programmable Coolant, Cip Auger, Remote Jog, 10,000 RPM Spindle, S/N: 1051860

- 2005 Haas VF-2SS, with High Speed Tool Changer, 12,000 RPM Spindle, Programmable coolant, hours as of 5/6/25 5226 17700 tool changes, 24+1 Side Mount ATC, S/N: 44067

- 2000 Haas VF-3, with Chip Auger, 20 Carousel ATC, Remote Jog, run time 5503 tool changes 349156, S/N: 20186

- 2003 Haas VF-4SS, with Chip Auger, Programmable Coolant, 5th Axis Wiring, 24+1 Side Mount ATC, S/N: 32619

- Haas TR160 5 Axis Trunnion, with With Haas 32619

- 2004 Mori Seiki NV4000 DCG, with 12,000 RPM Spindle, Mori Seiki MSX-501 Control, run time 5741 hours, Pallet Changer, Airflow air filtration system, Turbo Systems Model 5475-8766 Chip Conveyor, S/N: NV401DH0368

- 2004 Mori Seiki NV4000 DCG, with 12,000 RPM Spindle, Mori Seiki MSX-501 Control, run time 730 hours, Pallet Changer, Airflow air filtration system, Mayfran Chip Conveyor, S/N: NV401DA0098

- 2002 Roku Roku Sangyo GR-658N, with Fanuc Series 16iM Control, Kanto Seiki Model MLSF-07A-NM1, Amano Model Pia-30M, S/N: C032

- 2003 Haas VF-9B/40, with 24+1 Side Mount ATC, Cat40, Chip Auger, High Intensity Lighting, S/N: 30658

- 2007 Haas VF-2SS, with 12000 RPM Spindle, 24+1 Side Mount ATC, Chip Auger, Run Time 21025 tool changes 145946, S/N: 1057313

- Haas HA5C Indexer, with Near VF-2SS, S/N: 506012

- 2005 Haas VF-2SS, with 12,000 RPM Spindle, 24+1 Side Mount ATC, Programmable coolant, Chip Auger, Run Time 18645 Tool Changes 364903, S/N: 43183

- 1998 Haas VF-2 *PARTS*, with PARTS MACHINE, S/N: 16888

- 2000 Fanuc Robodrill A-T14ia, with Pallet Changer, Fanuc Series 16i M, 8838 Cut Hours, 14+1 ATC, BT30, S/N: P001TH846

- 1998 Fanuc Robodrill A-T14ia, with Fanuc Series 16i M, 14+1 ATC, BT30, S/N: P985TH718

- Kitamura Mycenter HX400i, with 13000 RPM, Pallet Changer, Bunri Chip Conveyor, 100 ATC, Fanuc Series 16im Control, 784 Cut Hours, S/N: 42568

- Okuma MC-V4020, with OSP-U10M Control, S/N: 082000-0091

- Makino A66/40, with Professional 3 Control, Pallet changer 2 Pallet, CAT40, S/N: MM-0180

- Makino A55, with Professional 3 Control, Through Spindle Coolant, Spindle Hours 29084, ATC 30, 2 Pallet, Cat40, S/N: 932

- 2000 Matsuura ES-450HII, with Cut hours 19369, 2 Pallet changer, Fanuc Series 16i-M, Cat40, S/N: 614113

- 1997 Matsuura RA-3F, with Turbo Chip Conveyor, Yasnac Control, APC 2 Pallet, Cat40, S/N: 970512433

- 1998 Matsuura MC-600V-DC, with Dual Vertical Spindle, Dual 30 ATC (60 total), Turbo Chip Conveyor, Yasnac Control, Cat40, S/N: 980113216

- 2008 Matsuura Maxia ES-800V, with Matsuura G-tech 840DI Control, 30 ATC, Cat40, S/N: 17769

- 2008 Matsuura Maxia ES-800V, with Matsuura G-tech 840DI Control, 30 ATC, Cat40, S/N: 17771

- 1999 Matsuura MC-800V62, with Yasnac Control, 30 Atc, Cat40, S/N: 991013742

- 2000 Matsuura RA-2G, with Yasnac control, 2 pallet APC, Cat40, S/N: 213898

- 2000 Matsuura RA-2G, with Yasnac control, 2 pallet APC, Cat40, S/N: 213898

MICROLATHES:

- 2020 Hardinge GT27, with Max spindle Speed 8000 RPM, Fanuc Series 32i Model A Control, LNS Chip Conveyor, S/N: GG-291SP

- Levin Micro-Turn 2, with PARTS MACHINE, S/N: 338724

- Levin Micro-Turn 3, with Fagor 8025 Control, S/N: 790310

- Levin Micro-Turn 2, with Fagor Control, S/N: 920801

- ZV 27 GT CNC, with Fagor Control 8055i, Fongex Chip Conveyor

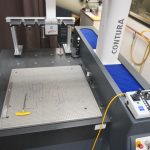

INSPECTION:

- REFURB 2016 Zeiss Contura Select 7/10/6, with Zeiss BP26_SE Standard Pendant Control, Vast XT Probe Head, Multi Sensor Rack, CALYPSO Software, S/N: 200508521540

- 2000 Zeiss Contura 7/10/6, with Zeiss BP26_SE Standard Pendant Control, Vast XT Probe Head, Multi Sensor Rack, CALYPSO, S/N: CMM200001521000

- 2008 Zeiss Contura G2 10/16/6 AKTIV, with Zeiss BP26 Standard Pendant Control, Vast XT Probe Head, Multi Se, CALYPSO nsor Rack, S/N: 200807501660

- 2016 Zeiss Contura 7/10/6 Active, with Zeiss BP26_SE Power On Pendant Control, Vast XT Probe Head, Multi Sensor Rack, CALYPSO, S/N: 731612531124

- 2005 Browne and Sharpe Global Image 7.10.7, with Renishaw PH10P Probe, Renishaw SCR200 Sensor Rack, Fixturing, Calypso, S/N: 0205-1414

- 2012 Micro Vu Vertex311UC, with 12x12x6 viewing table, S/N: VX311UCO1057

- 2006 Micro Vu Vertex 230, with Parts machine, S/N: VX23001006

- Keyence IM-6020, with Image Dimension Measuring System, IM 6500, S/N: SC113101

- Keyence IM-6225T, with IM 6700, S/N: 6C519010

- Keyence IM-6225T, with In original Packaging, Used

- ST , with Optical Comparator, Quadrachek 200 DRO, S/N: Y065102

- OGP OQ-20, with OGP Clip PLus Vision Controller, Optical Comparator

- 1999 OGP Basic Bench Optical Comparator, with, S/N: BB08051061

- Scherr Tumico Optical Comparator, with, S/N: Y120301

- Starrett Sigma HB350 Optical Comparator, with, S/N: 1466

- Keyence IM-6020, with with IM 6500, S/N: 9c112009

MANUAL EQUIPMENT:

- Chevalier FSG-1224ASII, with Surface Grinder, CNC control

- Jones Shipman 540, with Surface Grinder, XY DRO, S/N: BO 13755

- Taft Pierce , with Surface Grinder, Sony Magnescale LF-200

- Mitsui , with Surface Grinder, Walker Magnetic Chuck, Sony DRO

- Hardinge TFB-H, with Machine Lathe, S/N: HLV-H-7931 T

- Hardinge HLV-H, with Machine Lathe, S/N: HLV-H-10047-T

- Bridgeport EZTRAK, with Bridgeport CNC Control, EZ trak S/N EZ1-BV-E278, S/N: J312358

- Mitsui , with Surface Grinder, Neutrofier II, Sony DRO, Walker Magnetic Chuck

- MSO EMES, with Grinder, S/N: 23217

- Hardinge HLV-H, with Machine Lathe, Sony DRO, S/N: HLV-H-790-6096

- 2013 Hwacheon HL-460, with HL 18″ x 40″, Machine Lathe, S/N: 228447

- SWI Sport machines K3, with ProtoTrak M2 Control, S/N: 99-0595

- Bridgeport Series 1 with prototrak retrofit, with 2016 Prototrak SMX Control s/n 14045, S/N: J295657

- 1955 Monarch Engine lathe, with 12.5″ swing, distance between centers 20″, S/N: 40697

- MicroVU Comparator, with Quadrachek 2000 DRO

TOOL AND SUPPORT:

- 2013 Stoelting AQF-212, with Parts Cleaning Line, S/N: 5131977

- 2011 LMT Cobalt GM Laser Engraver, with Auto Door Laser Machine, S/N: 4963

- Smart Skim Coolant Skimmer system with tank, with Pumps, 4 Filter Tanks, Micromag pump, S/N: 9690

- Societe Genevoise MP-2P, with Jig Boring Machine, S/N: 673

- Granite Surface Plate

- Vises

- Arbor Presses

- Angle Plates

- Work Benches

- Shop Vacs

- Hydraulic Lift Carts

- Material and Materia Racks

- Parts Cage

- Tombstones

- Vises

- Work Benches

- Tooling

- Freddy Portable coolant sump pump

SAWS:

- Dake Johnson VH-24, with Vertical Metalcutting Bandsaw, S/N: 186317

- Hydmech H-14, with Horizontal Metalcutting Bandsaw, S/N: 50101331

MISCELLANEOUS SUPPORT AND STOCK:

- Stock Area

- Pallet Racking

- Inventory Shelving

- Packing Material

- Rolling Inventory Ladder, 10′

- Scales

- Offices

- Desks

- Yale 182G, with 2500 lb capacity, Push Lift, Electric, S/N: 5047812-01

- Crown, with 2000 Lb Capacity, Push Lift, Electric, S/N: 1A192394

- Yale GLP060TENUAE080, with 6000 Lb Capacity, Solid Tires, Gas Lift, S/N: M513951

- 2000 SkyJack SJIII-3219, with Scissor Lift, S/N: 230792

- Tennant 7100, with Floor Cleaner

- Porsche Cayenne

- Yale ERP040VTN36TE084, with 3600 Lb Capacity, Electric, Triwheel, S/N: G807N03791K

- Collets

- Pedestal Grinders

- Work Benches

- Perishable tooling

- Tool Holders

- Stronghold Cabinets

- Economy DST, with Die Separator Table, S/N: DB 48169

- Hardinge HSL-59 5C Chucker

- Monarch Lathe

- Bridgeport Knee Mill EZ TRAK DX, with Bridgeport CNC control, S/N: J294758

- Solothurn Agathon 175-DIA Surface Grinder

- Jones & Shipman 540 Surface Grinder, with Walker Magentic Chuck Control, Heidenhain XY DRO, S/N: B013765

- Baldor Pedestal Grinder

- Airflow EZ Arm Fume Hood

- DoALL C-916M Horizontal Bandsaw, with, S/N: 527-97365

- AirFlow Dual EZ Arm Fume Hood

- Belt/Disc Sander